Cannabis Extraction Step

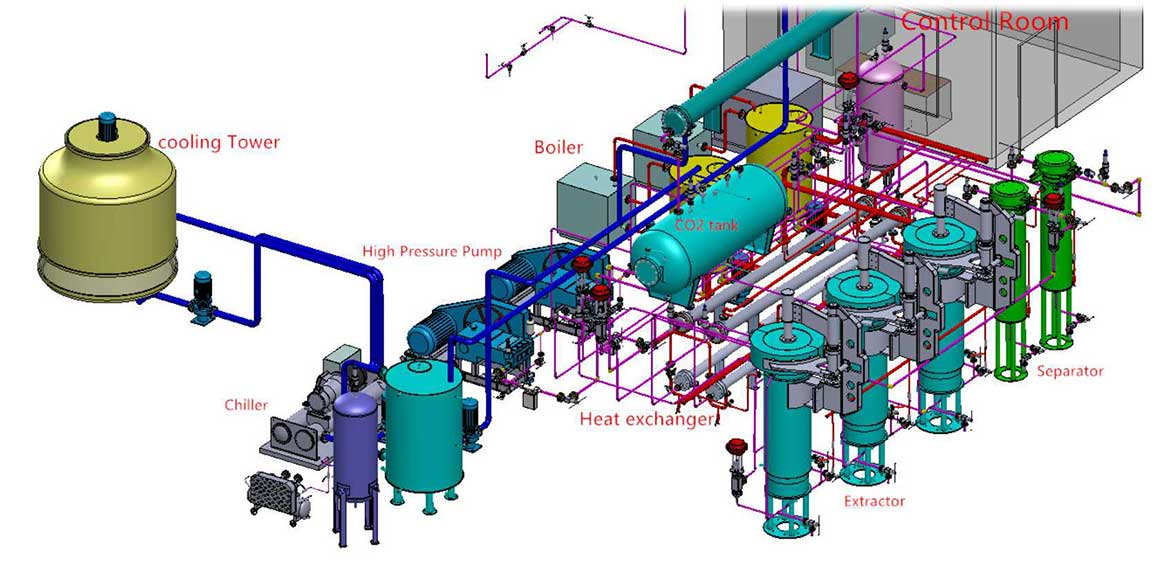

We use supercritical CO2 fluid as the extraction solvent and recycle it in the same system, which not only has simple process and low energy consumption, but also has small consumption of solvent and low price. Therefore, the extraction cost is low, and the extraction cycle is also short, only 1-2h, which is one quarter of the production cycle of the existing technology.And the extracted Cannabis oil has good quality, high purity, no odor, no solvent residue, no environmental pollution and other characteristics.

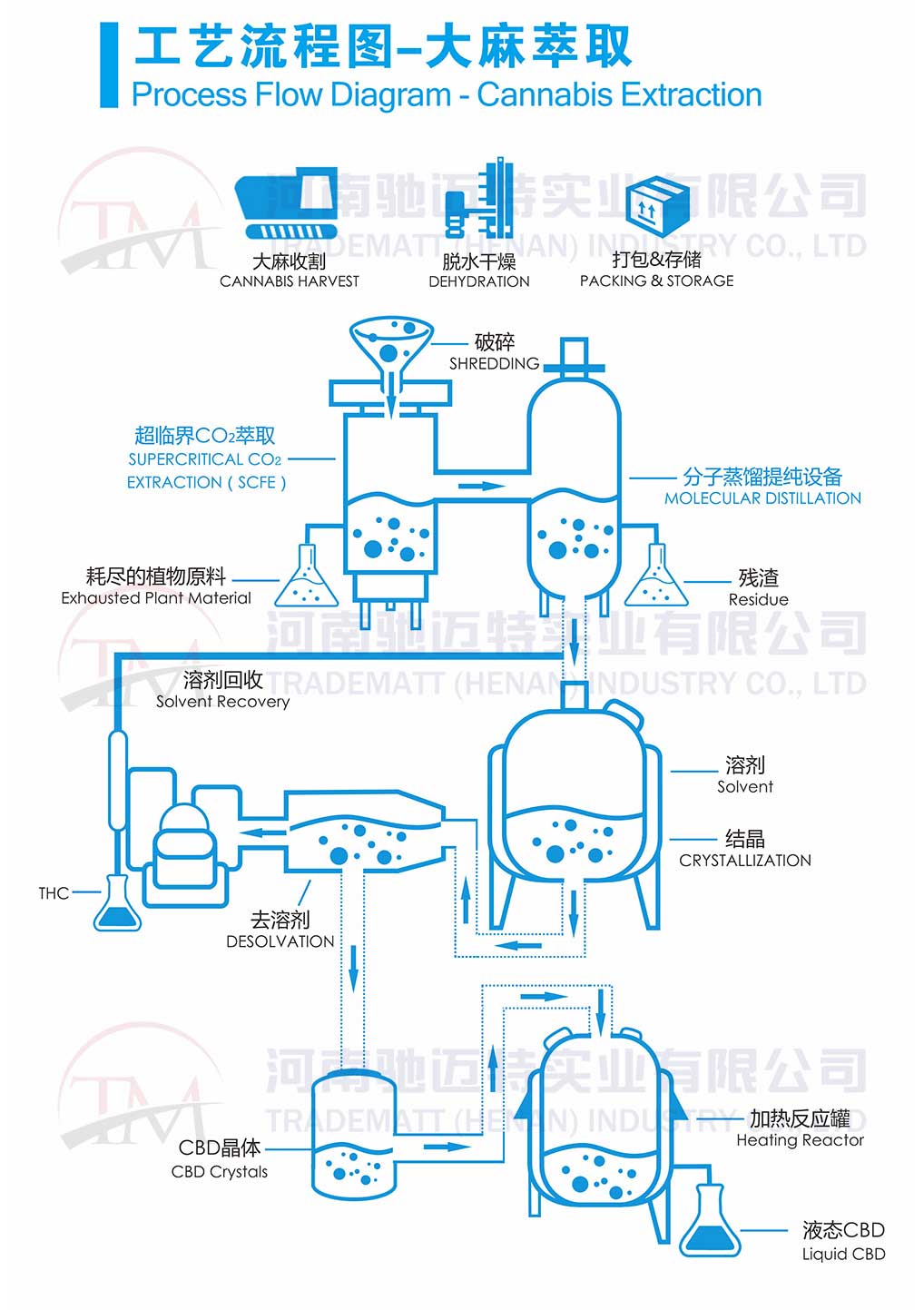

1. (1) Industrial Cannabis was screened, pre-drying, pulverized, dried and cooled before extraction

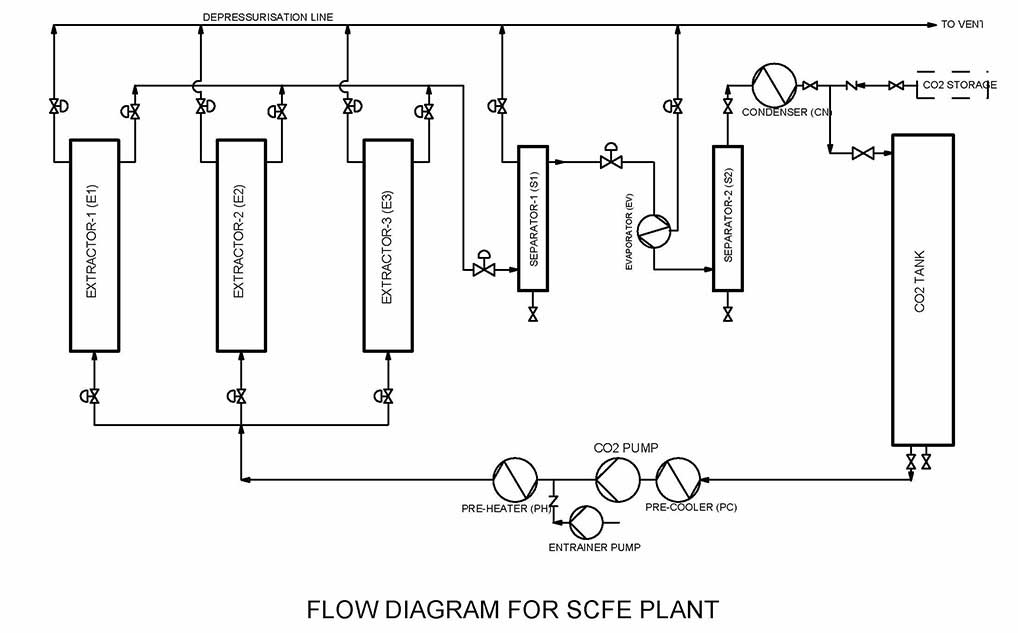

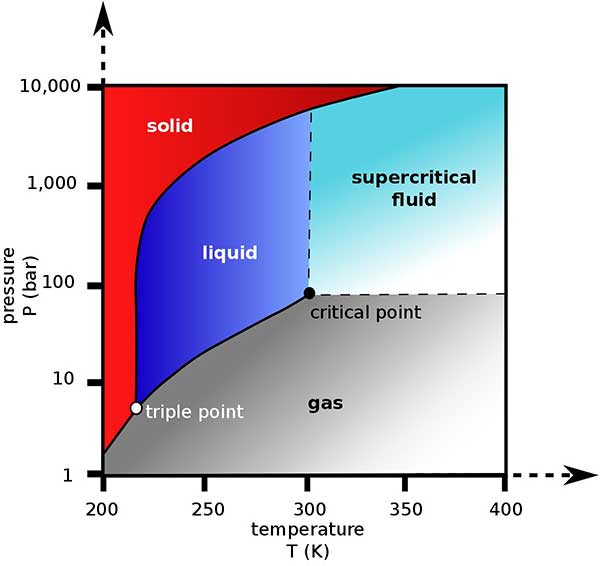

(2) During the extraction, the industrial Cannabis powder treated by step (1) was put into the material barrel of the extraction,the CO2 gas was injected into the extraction kettle, the temperature and pressure in the extraction kettle were kept in contact with the raw material under the supercritical state of CO2 gas, dissolve the industrial Cannabis oil rich in cannabidiol in the supercritical CO2 fluid

(3) CO2 fluid with cannabidiol-rich industrial Cannabis oil was expanded from the extraction kettle through throttling to the separation kettle, and the cannabidiol-rich industrial Cannabis oil was analyzed and collected

2. Screening refers to the screening of moldy raw materials in industrial Cannabis

3. Predrying refers to put industrial Cannabis in the oven, drying 10 ~ 12 hours under the 50 ~ 60 ℃ temperature or drying to the water content of industrial Cannabis is not greater than 8%

4. The pulverization, drying and cooling steps are to put the predrying industrial Cannabis into a pulverizer and pulverize it into industrial Cannabis powder of 20-40 mesh: then put the industrial Cannabis powder into the oven and drying 10 to 12 hours at a temperature 50-60℃. The industrial Cannabis powder after drying is left in the drying oven and naturally cooled to normal temperature.

Through the two drying processes of pre-drying and drying, the moisture in the raw material can be greatly reduced, and the conditions for reaching the supercritical temperature and pressure of CO2 can be reduced during the extraction, so that the extraction can be completed at a lower temperature and pressure, which can be efficiently performed. Also the can extend the life of the device. The pulverized material can fully contact with the supercritical CO2 fluid, which can greatly increase the extraction rate.

5. The supercritical temperature is 50~60℃ and the pressure is 30MPa.The flow rate of CO2 gas through the extraction kettle is 150~200kg/h, and the extraction time is 1.5~2h

6. The analytical conditions of the separation kettle were temperature 60~65℃ and pressure 5.0MPa

7. Collection means that the industrial Cannabis oil rich in cannabidiol extracted from the same batch of raw materials is rapidly put into the homogenizer after heating in the range of 70-80℃.After homogenizing filling, keep in cool storage away from light

3.Research Team

3.Research Team